Milking parlour: Typical errors that have a tremendous impact on milk quality

When was the last time you visited your client’s milking parlour? You must be well aware that small mistakes during the milking process can have a very significant impact on the quality of milk produced. Find here a review of these typical mistakes and tips on how to avoid them in order to improve udder health in the farm.

We’re going to focus on the 3 most important aspects that need to be checked during a farm visit:

1. The waiting area

The waiting area should be big enough for the number of animals (1.3 m2/cow), with a slope that ascends to the milking parlour (approx. 2-3% gradient).

It must be ensured that the last cow to pass through has not spent more than 1 hour in the waiting area.

It is important that cows don’t spend too much time in the waiting area. The last cow to pass through has not spent more than 1 hour in the waiting area.

If the client has a metal fence to move the animals closer to the parlour, its purpose is not to squash the animals, but rather to reduce the amount of space so that the animals voluntarily move towards the parlour.

2. The milking routine

We know that you are familiar with the processes (if not, check these blog entries: Efficient milking routines, Milking routines: unit attachment and alignment and Reducing de risk of bovine mastitis), whether the routine is complete or incomplete.

We are simply going to go over some simple yet key points to help detect errors quickly, starting by assessing the preparation of the teats using a paper towel.

CLEANING:

1. Does the pre-dip fully cover the teat?

2. Cover the length of the teat with a paper towel after applying the pre-dip and look at the surface covered. Has it been applied for long enough to work? (This should be around 30 seconds)

3. Is the tip of the teat clean? Make sure you check this key point after cleaning.

PLACING OF THE TEAT CUPS:

1. Are they straight?

2. Twisted?

3. Can you hear air entering and loss of vacuum?

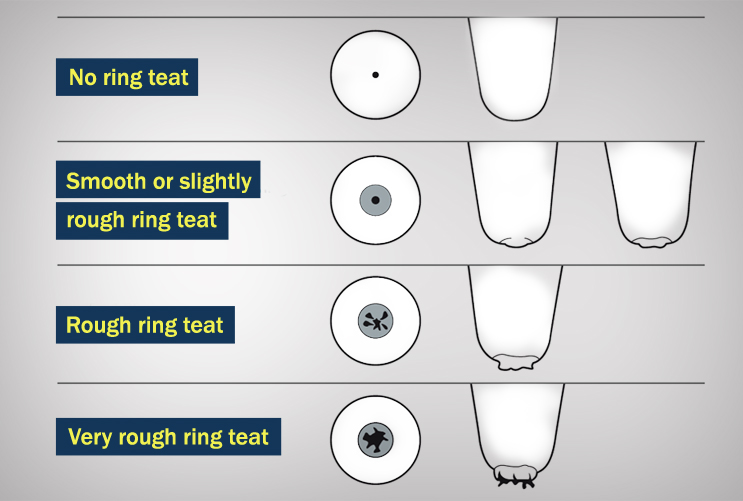

3. Hyperkeratosis

What is there to say about hyperkeratosis? It is a sign that the milking has been too aggressive.

It might be a sign of excess milking time or that the machine’s vacuum setting is incorrect.

Teat end condition evaluation. Adapted from Mein et al, 2001.

The parameters shown above are easy to measure and can provide valuable information about the performance of our clients’ milking machines and plays a key role in bovine mastitis prevention!

As promised at the beginning of this post, we have presented 3 easy-to-measure factors that can give you an idea about the quality of the milking process.

The next time you head to the milking parlour, check these parameters and tell your client what you have noted, does he or she agree? Why not discuss it with a cup of coffee?

They will appreciate the discussion about how to improve udder health in its farm, for sure!