Milk Management: What is the best teat dip to use?

After analyzing several aspects of teat dips in previous entries (the best substances to be used, the surrounding research or the opinion of veterinarians on this matter), we must now conclude with the following statement: the best teat dip is the one you can afford and the one that addresses the majority of your problems on the farm.

The best teat dip will result in the best cleaning and disinfecting of the skin of the teat (1,000 times less bacteria or 99.9% reduction of the bacterial load and the removal of physical dirt on the skin) (Watters, R., 2011).

Resulting in the highest level of hygiene for the milk quality (Cook, C., 2002):

- Poor hygiene: up to 2 g faecal material in 20 kg milk

- Good hygiene: up to 0.2 g faecal material in 20 kg milk

- Very good hygiene: up to 0.04 g faecal material in 20 kg milk

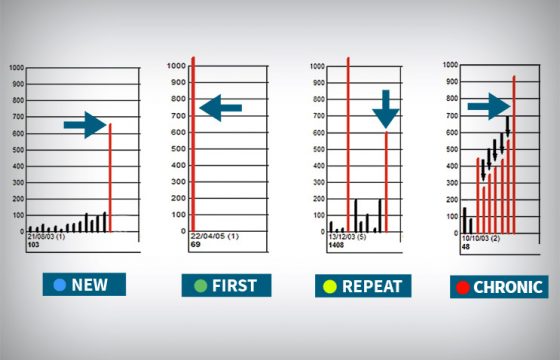

We should always look at the cow and quantify the data (No. Clinical cases/new Intramammary infections, teat end condition scoring, etc.) as she will show us the errors of our ways!

From damage to the skin and teat ends, as a result of incorrect management of the four pillars of udder health (Milking machine, Milking routine, environment and cow).

The damage caused by the incorrect management could result in protracted periods (as long as 3 to 5 weeks to heal even with teat dips that are aimed at protecting the skin against chemical irritants) of treatment with little to no reduction in the number of new bovine mastitis as there is no reduction in the risk.

It is not only the active that determines the efficacy of the teat dip, it is how effective we are at supporting the product!

E.g. drying the teat post application, how we mix and store the dips (water hardness, pH and bacterial counts reduce the efficacy of dips that need to be mixed on farm to the prescribed dilution) getting sufficient coverage of the skin (spray < dip), avoid contamination of the solution (teat dip cups), etc.

There are also other factors that could have more of an effect on the condition of the skin and teat e.g. ambient temperature, milking duration, and teat dip pH (Ohnstad, I., et. al., 2007).

An Ready To Use (RTU) dip would appear to limit errors (incorrect concentrations or incorrect products being used), and the good manufacturing practices would have to be upheld meaning that the product meats the safety and efficacy claims.

OTHER FACTORS TO CONSIDER

Additional aspects that are also worth to consider are the correct storage of the product, using non-expired stock or discarding product that differs from the manufacturer’s description of the product, and finally always read the directions on how to use the product.

The best product is the one that is applied in a way to cover all teat surface of all teats, in every cow, every milking.

Author: