4 Tips to Check your Milking Vacuum avoiding Mastitis in Cattle

Here we go again, annoying you about the importance of checking your milking machine to prevent mastitis in cattle. Remember, this simple parameter is very important as regards mastitis in cattle, because your cows will be exposed to correct -or incorrect milking- at least twice a day.

Why are we so insistent about checking the vacuum in the milking machine?

Because incorrect maintenance of the milking machine can make the trip to the parlour a nightmare for the cows. Our goal should be to achieve a fast, complete and gentle milking of the cow, which is how we prevent mastitis in cattle!

In previous posts we gave you some key points about visually checking the milking parlour, and also some key points to check, such as for instance the regulator capacity (static test).

Now it is time to briefly review some key points about vacuum pulsation, which we may not be familiar with, but it plays a huge role in mastitis in cattle.

1. THE DYNAMIC OR WET TEST:

A proper pulsator function is critical to the success of the milking process. Milking-time tests are the most direct method to determine the adequacy of vacuum production and vacuum regulation in any milking system. More detailed testing can be used to diagnose the cause of failure for either of these tests.

- The number of times per minute that the pulsator alternates between the milking and massage phase is called the PULSATION RATE. Rates vary from about 40 to 80 pulsations per minute, depending upon the manufacturer. A rate between 50 to 60 is usually recommended.

- The pulsation rate counts the total change of phases during milking, but there should be a ratio between the times of each phase. The ratio of time the inflation is in the milking phase compared to the time it is in the massage (rest) phase is called the PULSATION RATIO (or milk to rest ratio). Ratios vary by manufacturer, from 50:50 to about 70:30. Cows will usually milk slightly faster with a wider ratio, such as 70:30. However, the longer milk phase and shorter rest phase may cause teat end trauma and damage if the milking equipment is not working properly and if good milking practices are not followed, these factors are crucial in causing mastitis in cattle. Ratios near 60:40 are less likely to contribute to problem situations.

2. HOW TO CHECK THE PULSATION RATE AND RATIO:

You need a vacuum recorder; it can be a single-channel unit or multi-channel vacuum recorder. You will also need at least 4 teat cup plugs for correct testing of the pulsators.

Because most pulsator testers include an option for measuring the vacuum level, the pulsator test unit can be used as an accurate digital vacuum gauge and for measuring vacuum stability in the milkline and claw.

3. CHECK THE PULSATION SYSTEM:

Pulsator Testing is done with milking units connected, pulsators operating and liners fitted with teat cup plugs.

The objective of these tests is to determine if the pulsation system and all the pulsators are operating according to the manufacturer’s specifications. Pulsation testers are used to determine the pulsation rate and the duration of the four phases of pulsation.

4. THE MAIN PARAMETERS OF INTEREST FOR PULSATORS:

What is Pulsation?

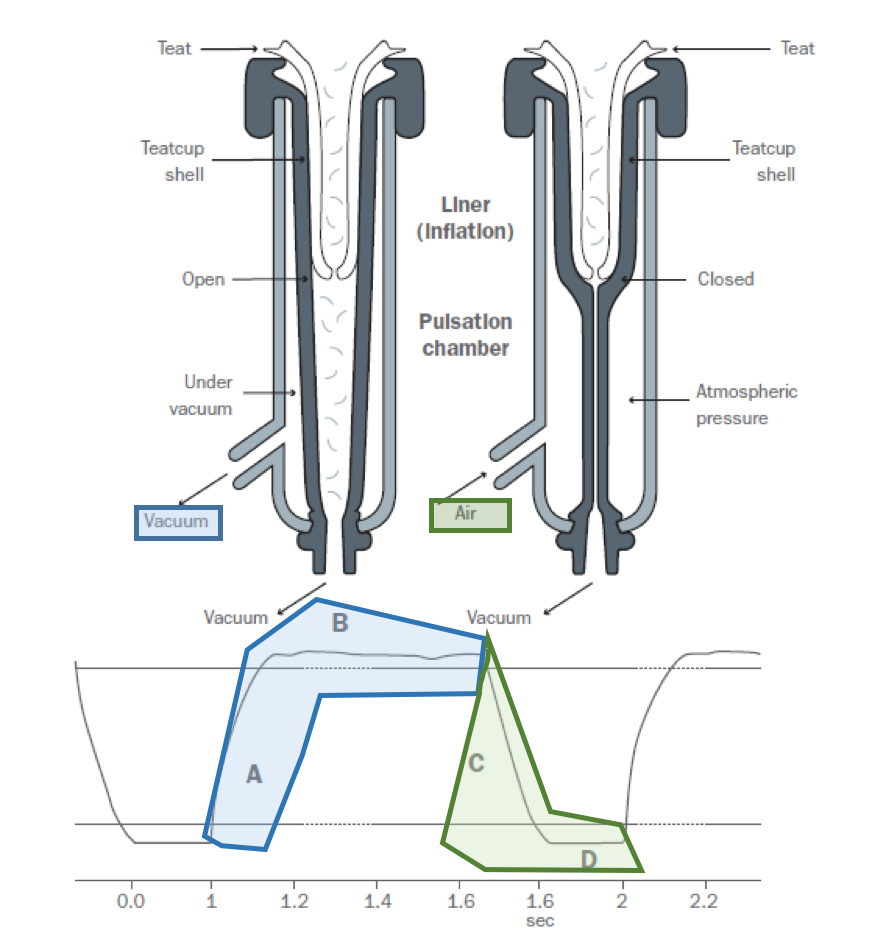

The ISO standard definition of the pulsation ratio is the proportion of the opening and open phases, named a+b in the figure, to the closing and closed phases, named c+d, of the pulsation cycle.

From about 1967, pulsation was defined more specifically as ‘cyclic opening and closing of a teat cup liner’. At about the same time, the term ‘pulsation ratio’ was used in a few scientific papers to define the proportion of time – within each pulsation cycle – that the liner was more than half open.

In the USA, this concept was adapted to define the ‘milk: rest ratio’ for a given liner based on its ‘touch point’. A milk:rest ratio of 60:40, for example, implies a ‘milking phase’ of 60% of each pulsation cycle followed by a ‘massage phase’ of 40%. The two phases are assumed to start and stop at the point where the liner walls first touch each other when measured with no teat in the liner.

Methods for defining pulsation in terms of liner wall movement rather than pressure changes have also been proposed (Spencer and Jones 2000; Spencer 2003; Mein and Reinemann, 2009).

The Pulsator Ratio should not differ by more than 5 percentage points from the manufacturer’s specifications or from one pulsator to another.

- The B Phase (milking or liner-open phase) of pulsation should be at least 30% of the cycle.

- The D Phase (massage, rest or liner-closed phase) of the pulsation cycle should not be less than 15% and not less than 150 milliseconds (Reinemann et al., 2001).

For common liner types, this balance is achieved with a D-phase of 150 to 200 milliseconds and a B-phase of 500 to 600 milliseconds. The A and C phases of pulsation can vary according to the volume of the pulsation chamber, length of long pulse tubes and restrictiveness of pulsator air ports (Reinemann, 2010).

Now you have the information needed to check if the teat ends on your farm can be improved, remember, the teat end is the door through which pathogens could pass to create mastitis in cattle, so, the better condition it is in, the more difficult it becomes for pathogens to create mastitis in cattle!

Content originally created for “the Mastipedia”.

Authors: Nicola Rota (Udder health and milk quality consultant).