Correct Vacuum levels: Can they help to prevent mastitis in dairy cows?

In previous posts we’ve seen how different tests for checking the vacuum pump can help you to prevent mastitis in dairy cows. Here you’ll find a few numbers and ranges regarding vacuum levels to help you know if the results of these tests are appropriate or not.

Remember that if the average milking time is about 5 minutes, and a cow is milked 3 times per day, and we take in consideration the average milking period leigh is 305 days, we can affirm the following: the average cow will spend more or less 76h in the milking parlor during the lactation period.

We need to be sure that there’s no risk for mastitis in dairy cows caused by the milking machine!

Which are the correct Vacuum Levels?

ASAE specifies and ISO recommends that the performance criteria for vacuum stability in a milking machine is that the vacuum drop in or near the receiver does not exceed 2 kPa (0.6”Hg) during normal milking.

Normal milking is the time that milking units are attached to cows including events such as teatcup attachment and removal, liner slips and cluster falloff.

In addition, the vacuum should not drop more than 2 kPa (0.6”Hg) below the receiver vacuum at any point in the milkline for at least 95% of the normal milking period.

Where should I measure the vacuum?

The most useful sites of measurement are in the milkline, in or near the receiver (if necessary), and in the claw.

Vacuum at these sites should be recorded while the system is under full milk and air flow conditions, that is, while clusters are being attached, while all clusters are on cows, and then as clusters are detached.

Recommendations for test equipment have been presented previously for milking time tests as specified by the new ASAE standard S518 and Practice ASAE EP445, “Test equipment and its application for measuring milking machine operating characteristics,” and the revised draft international standard DIS/ ISO 5707.

These tests are performed in the receiver, milkline, and claw. The National Mastitis Council recommends measuring the bandwidth (maximum – minimum) claw vacuum during milking in the new “Procedures for Evaluating Vacuum Levels and Air Flow in Milking Systems” (Reinemann et al., 1996, Reinemann, 2007).

Previous studies provided recommendations for testing vacuum stability in the receiver, milkline and the range of vacuum at the claw outlet during milking (Muthukumarappan et al., 1995, Reinemann et al., 1996).

What is the acceptable range?

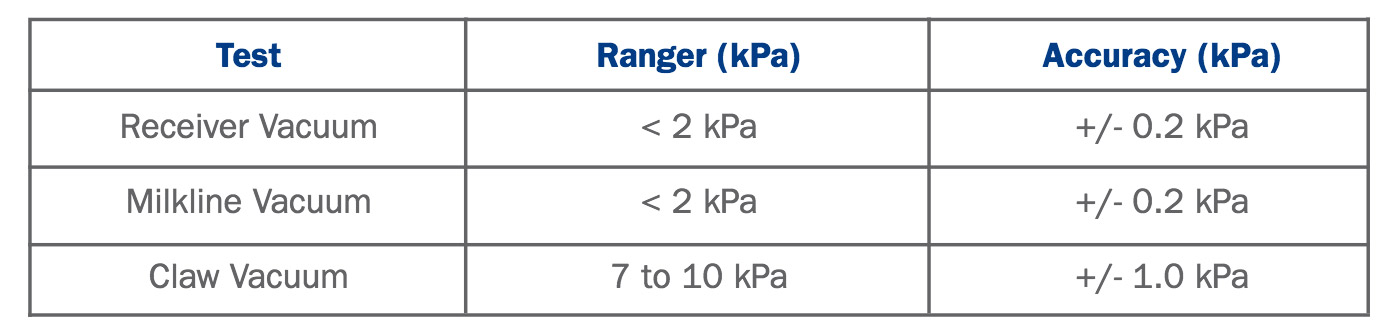

The range of vacuum fluctuations (maximum – minimum) prescribed in the NMC, ASAE and ISO standards and recommended accuracy for the milking-time measurements are as follows:

Operating vacuum is not a sufficient measure to characterize the quality of milking. Teat-end vacuum, milk flow patterns and the response of teats to the milking process are preferred indicators for evaluating milking system design and settings (Haeussermann and Hartung, 2010).

We will talk in next posts about the effect of vacuum in mastitis in dairy cows regarding the teat-end, which is influenced by milk flow level, milking system, system components and milking settings.

Thus, the optimal teat-end vacuum curve should show a vacuum between 26 to 39 kPa in the maximum vacuum phase (b) and a much lower and steady teat-end vacuum in the minimum vacuum phase (d).

During the complete time-span of the b-phase, the vacuum should be as constant as possible. High teat-end vacuum (33 to 39 kPa) should only be adjusted when the milk flow is higher than 0.8 L/min per quarter, because only then is the high vacuum also required for the transportation of the milk, resulting in more efficient milking (Ströbel et al., 2013).

Content originally created for “the Mastipedia”.

Authors: Nicola Rota (Udder health and milk quality consultant).

2 Comments

Good post!!

Thanks Rene!

Comments are closed.