Checking the milking parlour to increase milk quality and reduce mastitis in cattle

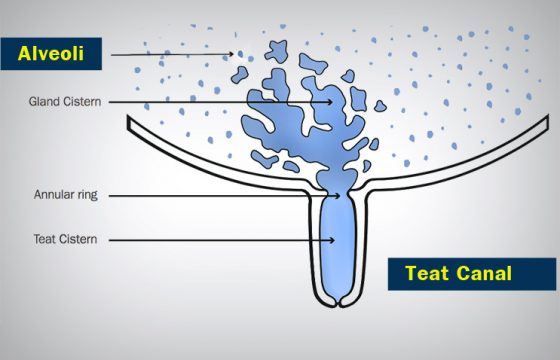

Everybody knows that to get milk from dairy cattle, the cow has to be milked. Use of milking machines is the easy way to rapidly and efficiently remove the milk without damage to the teat or gland and with minimal risk of the transmission of pathogenic microorganisms that might cause mastitis in cattle.

Description of the milking parlour

Knowing the milking machine is basic to prevent mastitis in cattle.

The basic milking machine functions are:

• Removal of milk from the cow by vacuum differential.

• The milk then flows to the receiver jar by gravity.

• The milk is pumped from the receiver jar into the bulk tank.

Milking system

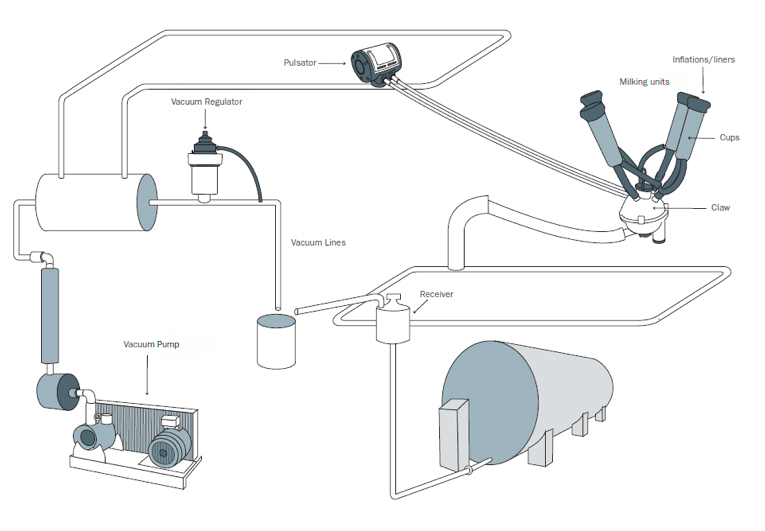

The milking system consists of the following parts:

• Vacuum pump: The pump removes air and creates the vacuum.

• Vacuum regulator: The vacuum regulator admits atmospheric air in and out of the system to keep the vacuum at a predetermined set level. If the vacuum gets too high, the vacuum regulator will open and let air into the system to lower the vacuum.

• Pulsator: The function of the pulsator is to allow intermittent massage of the teat end to prevent swelling and avoiding possible lessions in the teat that may end up in mastitis in cattle. It does this by alternating between a partial vacuum (milking phase) and atmospheric air pressure (massage phase).

Pulsator ratios of 100%, 50/50, 60/40 and 70/30 are typical ratios. The first number refers to the amount of time the pulsator draws vacuum to open the liner and withdraw milk. The second number indicates the amount of time it admits atmospheric air to collapse the liner and massage the teat. Uniform pulsation milks all 4 quarters simultaneously. Alternate pulsation milks two quarters at a time, while the other 2 quarters rest.

Dual pulsators allow the quarters to be milked at different ratios, such as 60/40 behind and 50/50 in the front quarters.

• Receiver: Milk flows by gravity through the milk line and into the receiver jar. The receiver jar serves as a small holding reservoir until the milk can be pumped into the bulk tank for cooling and storage. The valve between the receiving jar and the milk pump should not admit air.

If a bubbling action occurs in the receiver jar, air is leaking past the valve and it should be corrected or replaced in order to avoid the risk of contagious mastitis in cattle.

• Milking unit: The machine includes teat cups that are in contact with the cow’s teats and remove the milk, a claw where milk pools as it is removed from the four teats, vacuum tubes that provide vacuum to the teat cups and a milk tube that removes milk away from the claw, a source of vacuum for the machine.

Connecting tubes are divided into short milk tube (liner to claw), long milk tube (claw to milkline), short pulse tube (shell to air fork) and long pulse tube (air fork to pulsator).

Content originally created for “the Mastipedia”.

Authors: Nicola Rota (Udder health and milk quality consultant).